BLOG

December 2, 2025

Share this Article:

Accurate temperature sensing is critical to the performance and safety of many medical devices. In applications where temperature stability directly impacts patient care or equipment reliability, the need for consistent and precise measurements becomes a design requirement.

EI Sensor Technologies provides sensors for medical devices that deliver dependable performance in demanding environments. These

medical temperature sensors are built to ensure long-term accuracy, rapid response, and consistent output. OEMs rely on this level of control to meet regulatory standards and maintain device functionality over time.

The Importance of Precision Temperature Sensing in Medical Applications

Medical devices must operate within tight thermal tolerances, where even minor temperature fluctuations can impact performance or patient safety. Reliable sensing makes it possible to maintain these thresholds and support consistent operation.

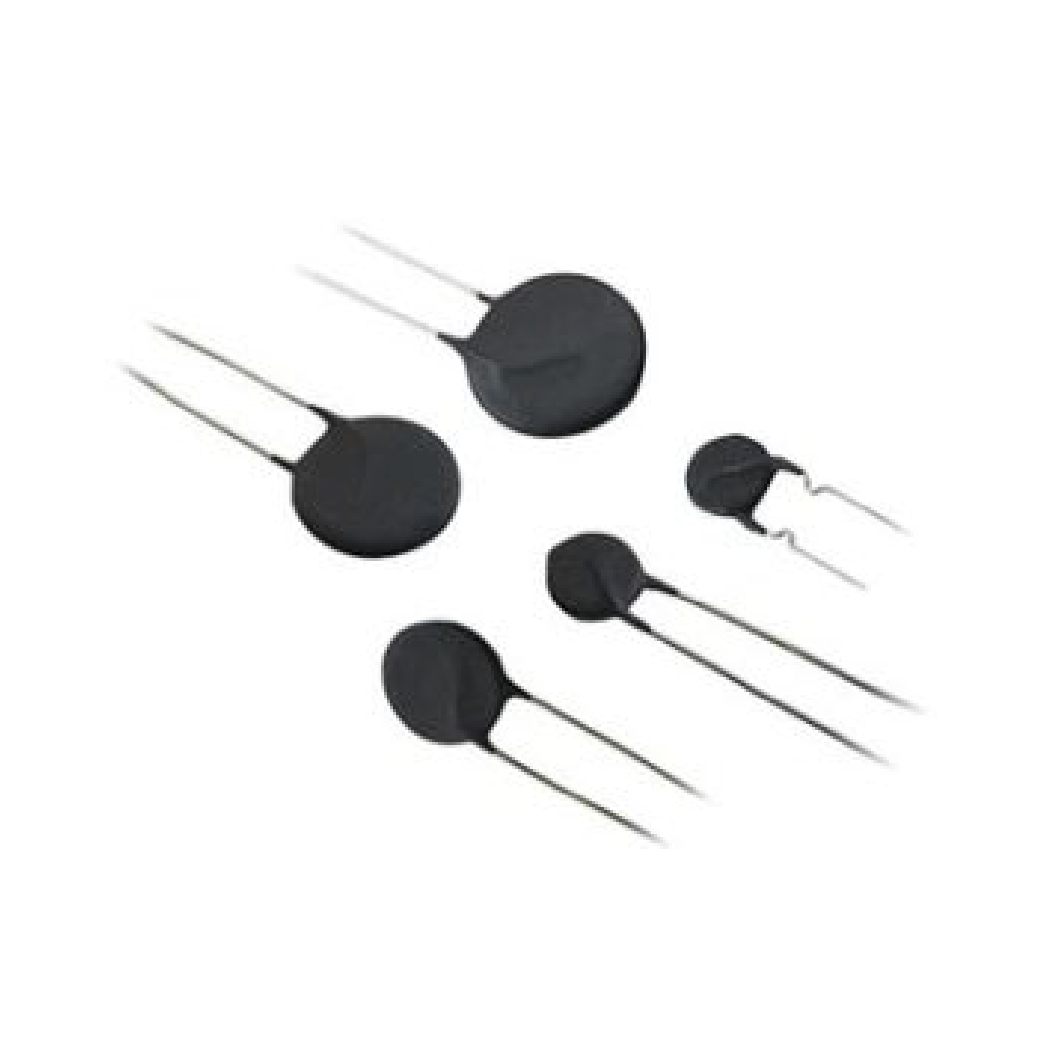

Applications such as fluid warming, tissue diagnostics, and powered patient systems depend on precise temperature inputs. Thermistors and RTDs are widely used for their accuracy, responsiveness, and ability to perform in compact spaces. These sensors help maintain system stability under different loads and ambient conditions, contributing to device longevity and regulatory compliance.

Patient Monitoring Applications

Precise temperature measurement is essential in patient monitoring systems, where real-time data influences diagnosis and clinical response. High-performance sensors enable both routine checks and advanced monitoring to operate within required thresholds.

Non-Invasive Monitoring

Devices such as digital thermometers, wearable health patches, and surface probes rely on compact, fast-responding thermistors to track body temperature accurately. These sensors offer high sensitivity and are well-suited for early detection of fever or thermal irregularities.

Clinical Environments

In critical care settings such as ICUs, surgical units, and neonatal wards, monitoring systems operate continuously. Sensor reliability, thermal stability, and precise integration help maintain device accuracy and safeguard patient health.

Invasive and Continuous Monitoring

In applications like catheter-based monitoring and intraoperative systems, sensors are embedded within devices that function inside the body. These components must deliver consistent readings over extended use while meeting biocompatibility and miniaturization requirements.

Sensor assemblies used in these environments often require specialized encapsulation materials and form factors that can withstand sterilization or prolonged exposure to fluids. Selection criteria may include thermal response time, insulation properties, and compatibility with catheter dimensions or biofeedback systems.

Lab and Diagnostic Equipment

Laboratory and diagnostic devices rely on precise thermal management to operate reliably. Temperature sensors help control system stability, reduce measurement errors, and support consistent testing outcomes.

Sample Handling and Analysis

Instruments such as blood analyzers, centrifuges, and immunoassay systems operate within tightly controlled environments. Medical temperature sensors regulate fluid temperatures, incubation zones, and reagent storage. Accurate sensing improves test consistency and protects sample integrity.

These sensors also play a role in maintaining instrument calibration, allowing instruments to operate consistently across regulatory audits and quality control procedures.

Imaging and Diagnostic Devices

MRI, CT, and ultrasound systems use sensors to monitor internal temperatures and manage heat buildup in sensitive components. Maintaining thermal balance helps protect electronics, enhance image quality, and maintain safe conditions during patient use.

Integrated Control Systems

Many diagnostic platforms rely on automated thermal control. Thermistors and RTDs deliver the responsiveness and accuracy needed for stable closed-loop performance. Selection often depends on size, tolerance, and durability in high-use environments.

Sterilization and Disinfection Processes

Effective sterilization depends on precise thermal control. Temperature sensors are used to monitor, regulate, and verify thermal conditions across a range of disinfection methods.

Autoclaves and Steam Sterilizers

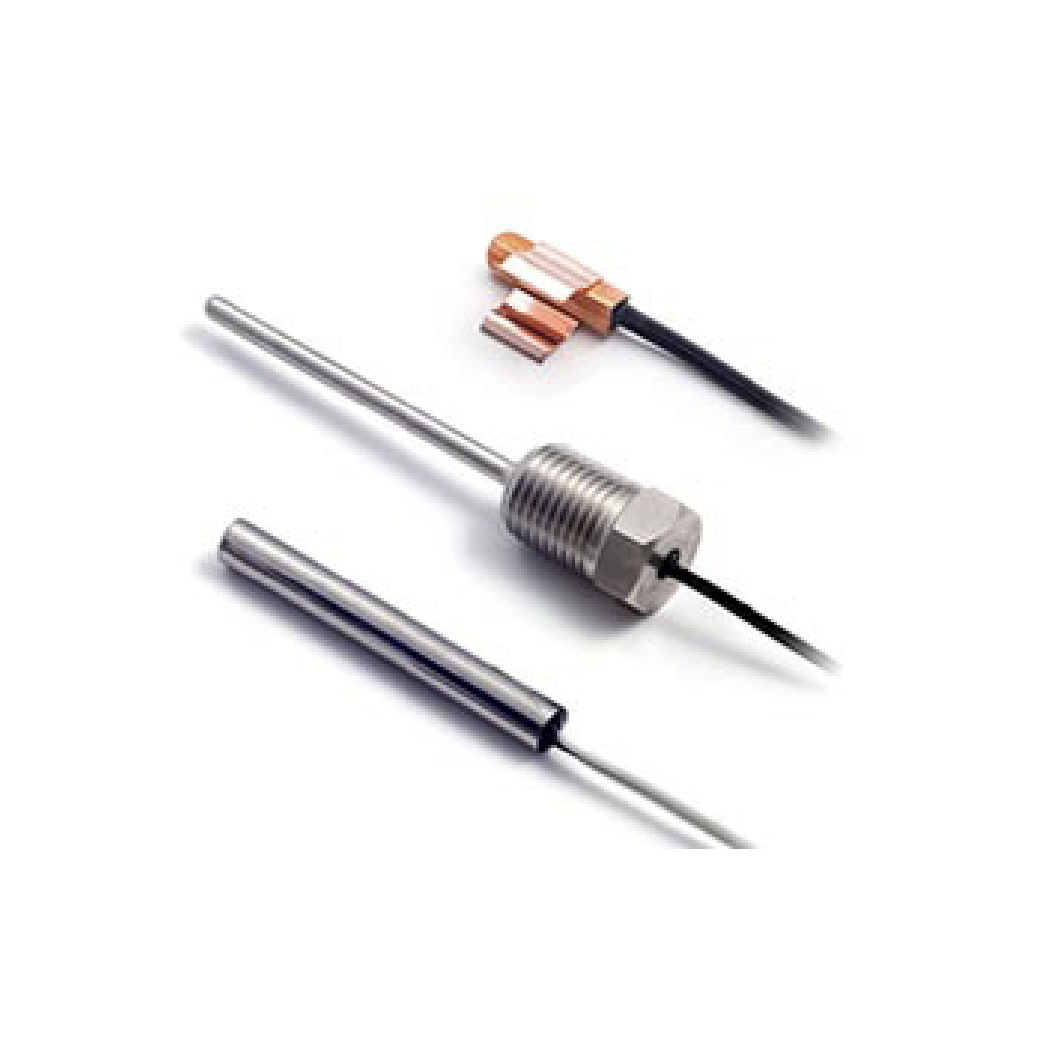

Steam sterilizers use high-pressure, high-temperature cycles to neutralize pathogens. Temperature sensors monitor internal chamber conditions to verify that required thermal thresholds are consistently reached and sustained throughout each cycle. Thermistors and RTDs are commonly integrated into chamber walls or probe assemblies to provide rapid, stable feedback during operation.

Chemical Sterilization and Disinfection Systems

Low-temperature sterilization methods using ethylene oxide or hydrogen peroxide gas also rely on accurate temperature monitoring. Sensors regulate the reaction environment and help maintain safe operating conditions, particularly when temperature-sensitive instruments are involved.

Washer-Disinfectors and High-Temperature Cleaning Units

Medical washers and disinfectors use heated water or solutions to clean surgical tools and reusable devices. Temperature sensors verify the effectiveness of the cleaning cycle by monitoring thermal levels in spray arms, tanks, or reservoirs. Reliable sensing helps facilities meet hygiene compliance standards while protecting device integrity.

Why EI Sensor Technologies is the Ideal Partner

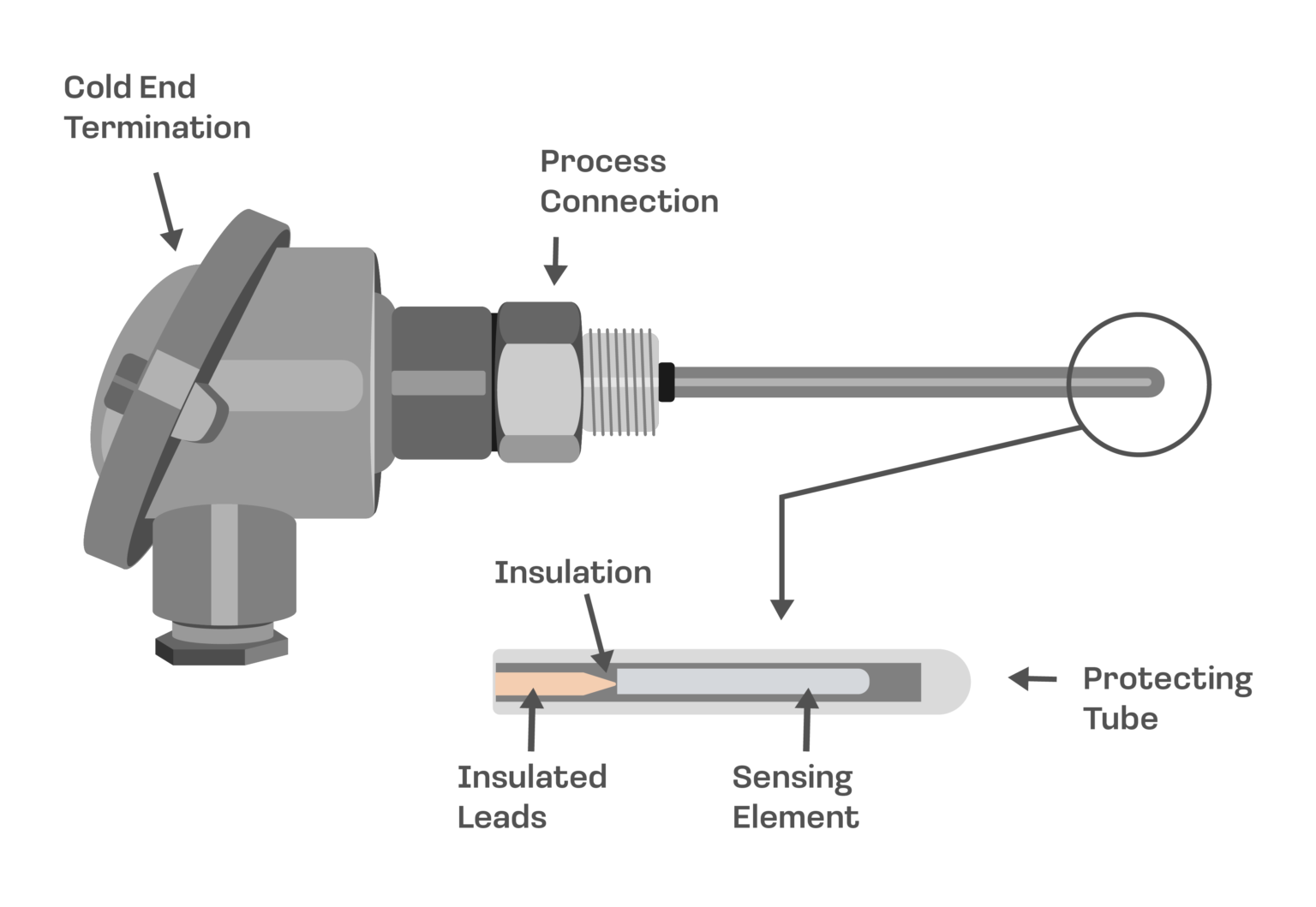

Medical device manufacturers need sensor solutions that deliver consistent accuracy, integrate easily into complex systems, and meet application-specific requirements. EI Sensor Technologies offers a full range of thermistors, RTDs, and custom probe assemblies designed for use in healthcare environments.

With over 30 years of experience, the team works closely with OEMs to develop components that meet performance, space, and compliance goals. Whether the need is for a miniature thermistor in a wearable monitor or a robust RTD for high-temperature sterilization equipment, EI Sensor provides options tailored to meet unique design challenges.

Most projects require more than off-the-shelf parts. That’s why EI Sensor supports custom solutions, backed by engineering guidance, responsive service, and a focus on long-term reliability.

Let’s discuss your temperature sensing needs.

Call or email us at sales@ei-sensor.com for engineering support or to request a quote.