BLOG

January 9, 2026

Share this Article:

Efficient temperature regulation is essential in HVAC systems. Accurate sensing helps equipment maintain thermal balance, optimize energy use, and respond to changing environmental conditions. Without reliable data, systems may overcompensate, cycle too frequently, or operate outside ideal parameters.

Thermistors and

RTDs are used throughout HVAC equipment to monitor temperatures in air handling units, refrigeration lines, compressors, and more. These sensors provide the precision needed to improve control strategies, reduce energy consumption, and meet performance targets.

The Role of Temperature Sensors in HVAC Systems

Temperature sensors are embedded throughout HVAC equipment to enable consistent system control. Their output is used to monitor refrigerant conditions, air temperature, and equipment surface temperatures. These readings guide operational decisions such as when to engage compressors, modulate airflow, or initiate defrost cycles.

In advanced systems, sensors provide continuous feedback for variable-speed components and digitally controlled valves. This level of control improves precision and supports demand-based operation. Without accurate temperature input, system responsiveness can suffer, leading to inefficiencies or uneven thermal performance.

The placement and specification of each HVAC temperature sensor is critical to achieving the desired system behavior. Proper integration helps manufacturers meet both functional goals and user expectations.

Boosting Energy Efficiency with Precision Sensors

Energy efficiency in HVAC systems depends on precise temperature data. Accurate readings allow system controllers to make real-time adjustments that minimize energy use without sacrificing performance. When sensors track temperature changes quickly and reliably, systems can reduce short cycling, maintain tighter setpoints, and avoid running longer than necessary.

Thermistors and RTDs are both well-suited for this role. Their fast response and stable performance over time make them effective for modulating fan speeds, controlling compressors, and adjusting refrigerant flow. These optimizations lead to measurable energy savings across a range of HVAC-R applications.

Using a high-quality

HVAC temperature sensor helps manufacturers and facility operators lower operating costs and achieve better system efficiency, especially in environments with variable loads or fluctuating ambient temperatures.

Meeting Environmental and Regulatory Standards

Modern HVAC systems must meet increasing demands for sustainability and regulatory compliance. Energy codes, refrigerant regulations, and building efficiency standards all place pressure on manufacturers and system designers to improve thermal control and reduce environmental impact.

Temperature sensors play a key role in helping systems comply with these requirements. Consistent thermal monitoring enables better refrigerant management, limits unnecessary energy use, and supports equipment operation within defined performance thresholds.

Accurate thermal data also supports documentation and system validation during audits or inspections.

Applications Across HVAC Components

Temperature sensors are used throughout HVAC systems to monitor and control key processes. Each application has unique performance demands, from rapid response times to long-term stability in high-moisture environments.

Evaporator and Condenser Coils

Sensors placed near coils help monitor refrigerant temperature and system load. This data is used to optimize compressor cycling and prevent coil freezing or overheating.

Compressor Systems

Monitoring discharge and suction line temperatures ensures the compressor operates within safe limits. Sensors also help detect inefficiencies that could lead to mechanical failure or reduced cooling capacity.

Air Handling Units (AHUs)

Sensors measure supply and return air temperatures to control fan speed, damper position, and reheat operations. Stable readings contribute to consistent indoor climate control.

Refrigerant Lines

Line sensors track superheat and subcooling values, which are critical to system balance. Accurate sensing improves charge diagnostics and overall system efficiency.

Defrost Controls

In refrigeration applications, sensors trigger defrost cycles based on coil temperature. This approach prevents ice buildup and maintains airflow without wasting energy.

Zone Controls and Smart Thermostat

Room-level sensors provide temperature data for zoning systems and smart thermostats. These inputs help optimize comfort and reduce energy use in multi-zone buildings.

Thermistors vs. RTDs: Choosing the Right Sensor

Both thermistors and RTDs are used in HVAC systems, but selecting the right sensor depends on application-specific needs such as temperature range, accuracy, size, and response time.

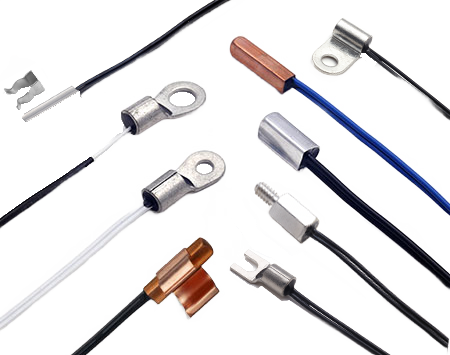

Thermistors are commonly used in HVAC applications due to their fast response and high sensitivity in narrower temperature ranges. They are ideal for monitoring air and refrigerant temperatures where compact form factors and cost-efficiency are priorities. NTC thermistors, in particular, offer a steep resistance change over small temperature shifts, which is beneficial for responsive control.

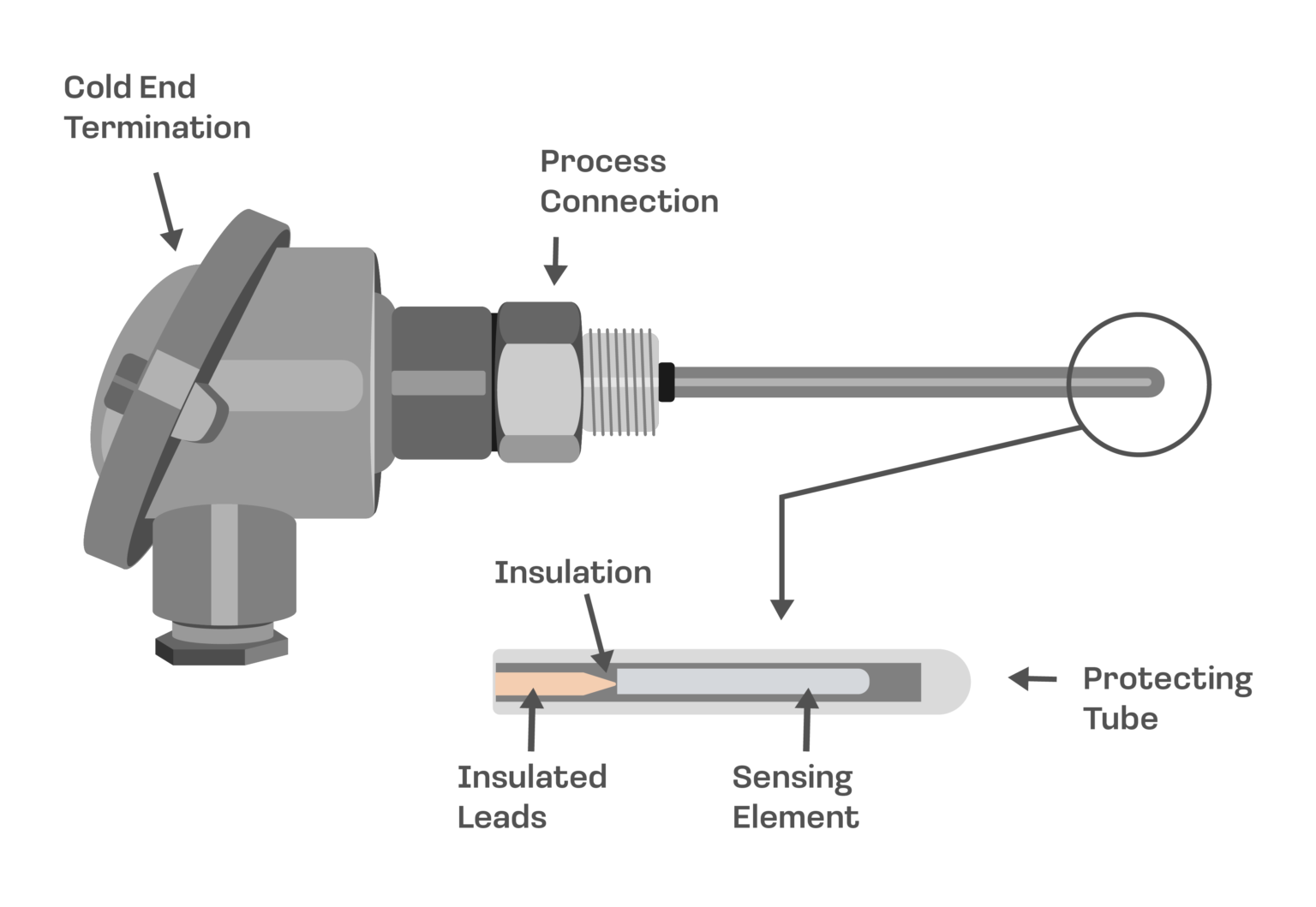

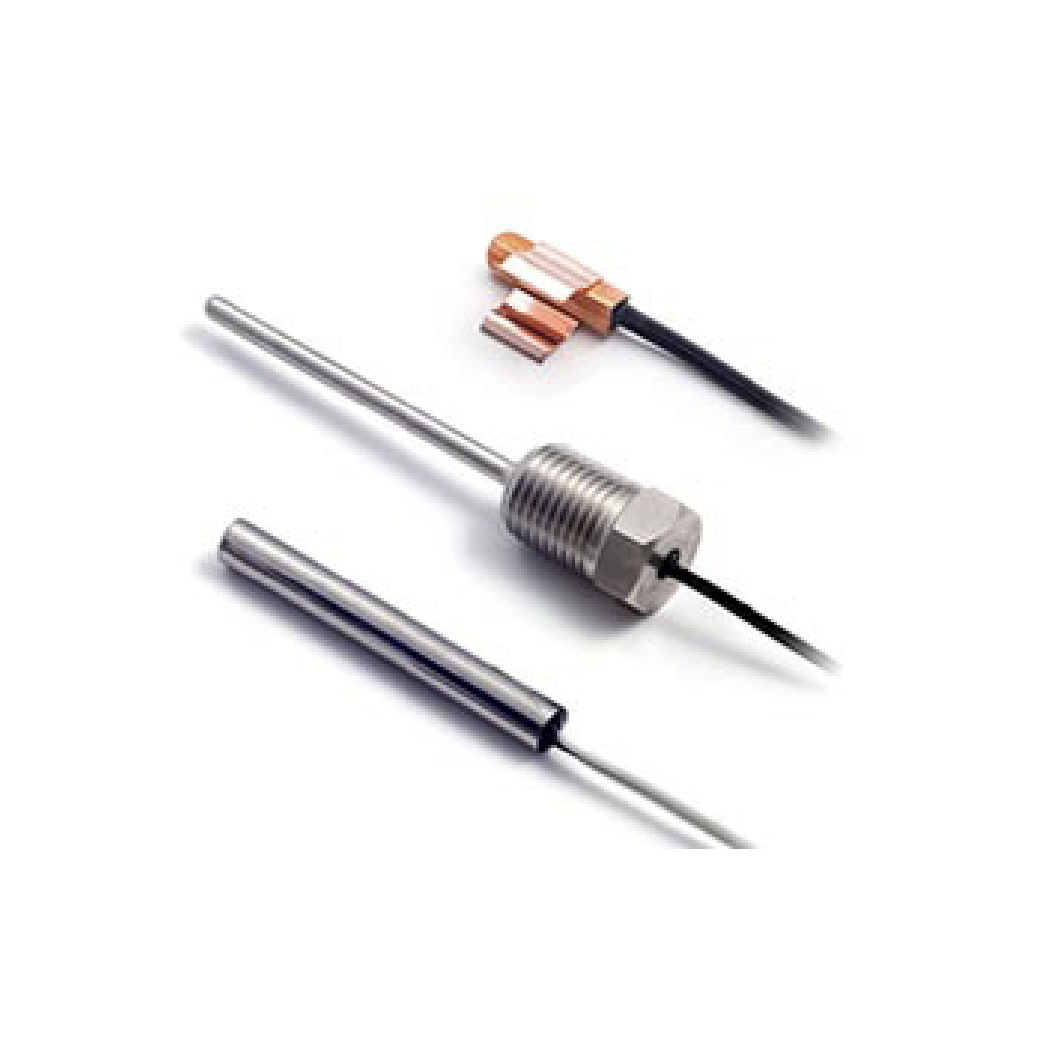

RTDs (Resistance Temperature Detectors) provide excellent accuracy and long-term stability across a wider temperature range. They are more commonly used in industrial or large-scale commercial HVAC systems where durability and precision outweigh cost concerns. RTDs are well-suited for components exposed to extreme or fluctuating conditions over extended periods.

EI Sensor’s Contribution to Smarter HVAC Solutions

EI Sensor Technologies partners with HVAC manufacturers to deliver high-performance sensing solutions built for today’s system demands. With decades of experience in temperature sensing, the team supports OEMs with both standard components and custom assemblies designed for energy efficiency, thermal control, and long-term reliability.

A wide selection of thermistors and RTDs is available for use in air handling units, compressor protection, refrigerant monitoring, and defrost systems. Each sensor is built for stable performance, quick response, and seamless integration with modern control platforms.

For applications that require a tailored approach, EI Sensor offers engineering support to modify tolerances, adjust packaging, or design fully custom probe assemblies that align with system specifications.

Get Started with EI Sensor Technologies

HVAC systems continue to advance in performance, energy efficiency, and compliance. EI Sensor Technologies provides the temperature sensing solutions required to meet these evolving demands through proven standard parts and custom assemblies designed for specific system needs.

If you're developing HVAC equipment and need reliable sensors or engineering input, we're ready to assist.

Email us at sales@ei-sensor.com to discuss your requirements, request a quote, or

connect with our technical team.