BLOG

January 9, 2026

Share this Article:

Inrush current limiters suppress the current surge that occurs when switching mode power supplies, motor drives, transformers, and other devices are turned on. The high initial starting current can harm these systems and components, so inrush current limiters are applied to minimize the spike and harmful effects. The most popular types of inrush current limiters are negative temperature coefficient (NTC) thermistors and positive temperature coefficient (PTC) thermistors.

What is an Inrush Current Limiter?

When the initial power is turned on, the initial current drawn by electrical devices is the inrush current, which can be many times higher than the normal running operating current. Failure to manage the initial current spike can damage equipment and its components or cause blown fuses and tripped circuit breakers. Current spikes can also reduce equipment reliability and durability, and stress power supplies, sometimes making the equipment inoperable.

Inrush current limiters are devices that prevent these spikes by limiting the amount of current at start-up and subsequently allowing normal current flow so that the system starts and operates as designed.

How Do Inrush Current Limiters Work?

Inrush current limiters minimize inrush current spikes. Inrush current limiters are often thermistors or thermally sensitive resistors whose resistance changes significantly due to the inrush current flow through the device. While there are several types of inrush current limiters, their core function is to minimize the current spike that occurs at turn-on from passing through and damaging the system’s sensitive components.

Their resistance drops significantly after initially limiting the current flow, and the reduced resistance allows the normal running current to flow freely, so the system starts and operates properly.

Advantages of Using an Inrush Current Limiter

Inrush current limiters provide a single device solution value by safeguarding systems, offering enhanced functionality, and providing design and cost advantages over alternatives.

Safeguard Systems and Components. Inrush current limiters limit the initial current surges that can damage sensitive components like capacitors, rectifiers, and power switches during turn-on. They also improve system reliability by preventing blown fuses and tripped circuit breakers that keep systems from operating or operating correctly. Excessive Inrush current also increases the wear on many components, so inrush current limiters extend the operational life of those components.

Design and Cost. Most inrush current limiters are small, so they easily fit on electronic circuits and in other applications where size matters. Thermistors are also an inexpensive single component solution compared to the complex active circuits that can be used as alternatives.

Types of Inrush Current Limiters

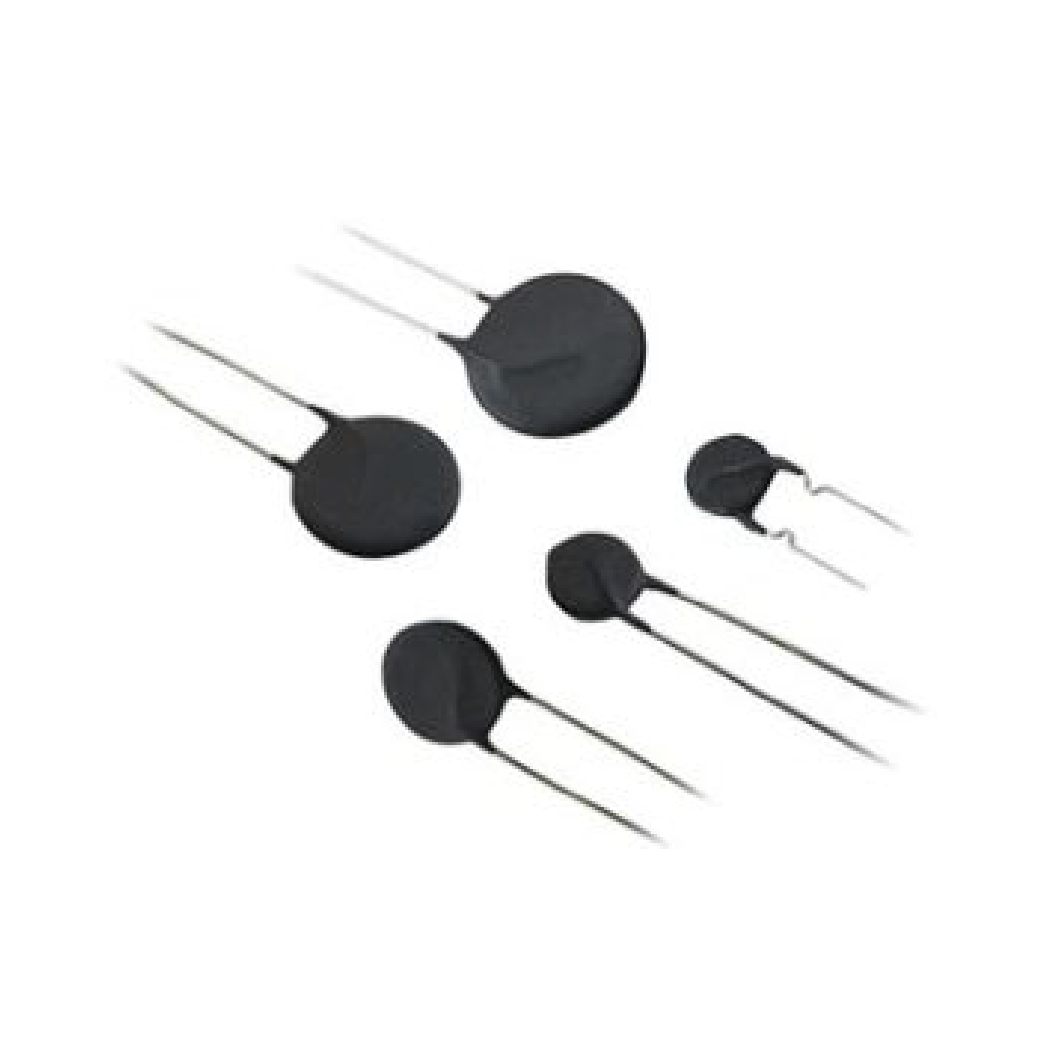

Negative temperature coefficient (NTC) thermistors exhibit less resistance at higher temperatures, while positive temperature coefficient (PTC) thermistors show more resistance at higher temperatures. While NTC thermistors are widely used as inrush current limiters, PTCs are advantageous for some applications.

Inrush NTC Thermistors

Negative temperature coefficient (NTC) thermistors are the most common inrush current limiters. Made of sintered metal oxides pressed into ceramic disks, they provide high room temperature resistance and prevent high turn-on current flows. After the NTC protects against the initial spike, it self-heats, and its resistance drops significantly, allowing increasing amounts of current to flow, which allows the system to start and operate correctly.

Inrush PTC Thermistors

While NTC thermistors are more commonly used as inrush current limiters than PTCs, PTCs are preferred for some applications.

Situations that use PTCs often involve ambient temperatures that are much higher or much lower than room temperature. When temperatures are high, NTC resistance may be too low to protect the system, while at low temperatures, it may be too high to allow the system to turn on.

Applications of Inrush Current Limiters

The primary application for inrush current limiters involves systems in which significant initial current surges can cause damage, particularly those with large input capacitors drawing a high initial current. Applications in which inrush current limiters offer value include those listed below.

Power Supply Components. Protects rectifiers and input capacitors from inrush currents

Motor Soft Start. Prevents current spikes when starting large electrical motors

Lighting Applications. Extends the life of fluorescent and halogen lamps by limiting the current surge when turned on

Medical equipment. Limits inrush current surges to medical devices with high power requirements, such as magnetic resonance imaging (MRI) devices.

Looking for an Inrush Current Limiter?

Your choice of inrush current limiters may vary based on the frequency of on-off cycles, voltage, cost, and other requirements. EI Sensor offers a range of standard and custom NTC and PTC thermistors you can order directly from EI Sensor or through our stocking distributors. Let us apply our expertise to solve a problem with inrush current limiters or ensure you use the best product for your application.

EI Sensor’s Inrush Current Limiters

If you have questions about temperature sensors or inrush current limiters, contact us for help. If our standard inrush current limiters do not meet your application needs, let’s discuss your requirements, and we can discuss developing a custom solution for you.