BLOG

January 22, 2026

Share this Article:

Temperature monitoring and control in large spaces comes with unique challenges. Airflow, sunlight, equipment heat, and insulation gaps can all create hot or cold spots. In these situations, one sensor may not give reliable temperature data that represents the average temperature across the entire area.

Thermistor averaging sensors are designed to solve that problem. They collect readings from multiple points, then produce a single averaged value. This approach helps systems operate more efficiently and respond more accurately to real conditions.

What is an Averaging Sensor?

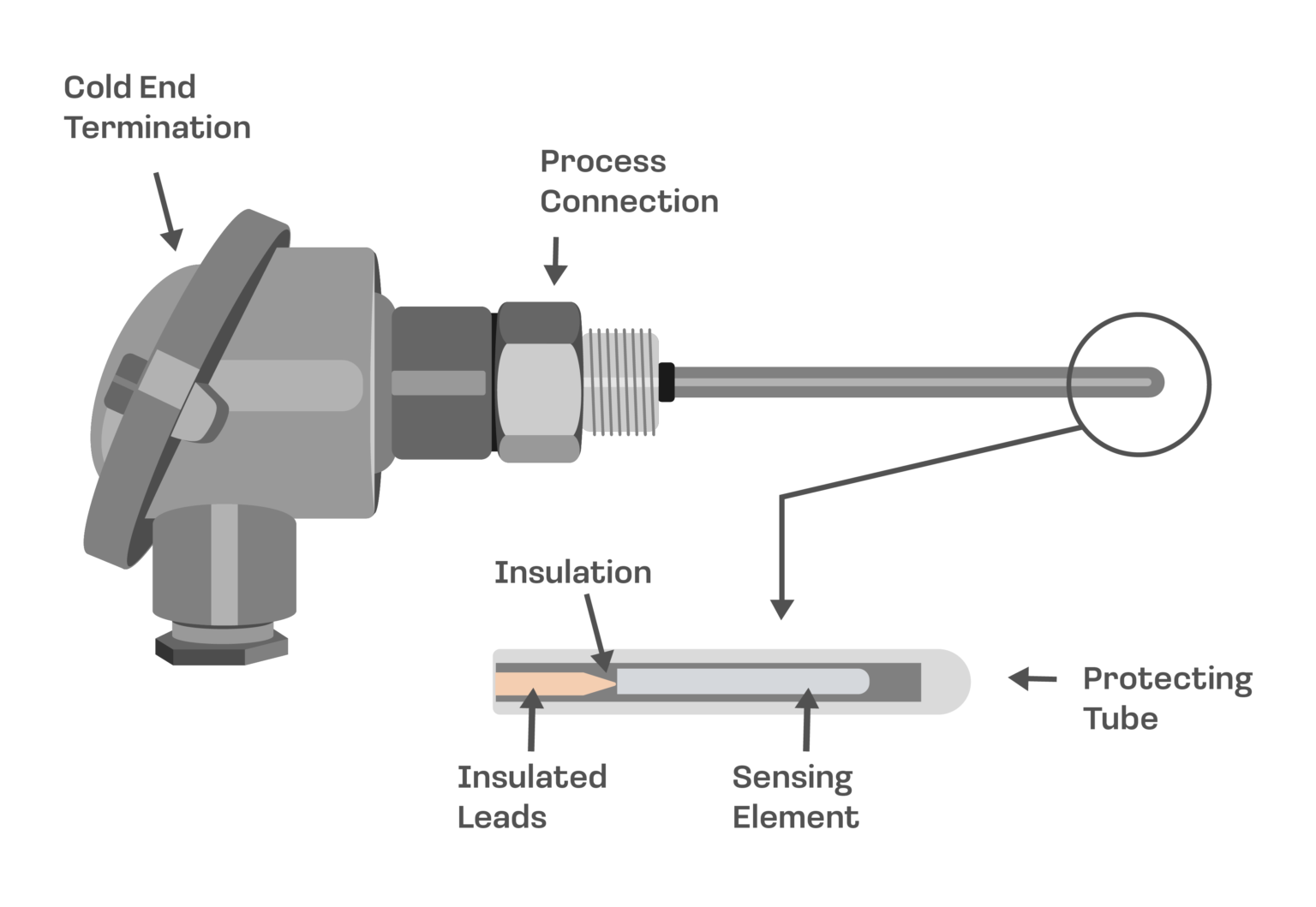

This is paragraph text. Click it or hit the Manage Text button to change the font, color, size, format, and more. To set up site-wide paragraph and title styles, go to Site Theme. An averaging sensor is a temperature-sensing device built to measure conditions across a wider area rather than a single spot. Instead of relying on one sensing element, it typically contains multiple sensing elements spaced along its length. These points are connected in a way that produces a single output value, representing the average temperature across the monitored area.

In thermistor averaging sensors, each sensing point uses an NTC thermistor. As temperature rises, resistance decreases. When wired together, the combined resistance gives a reading that reflects the full temperature profile of the space, not just a single point reading.

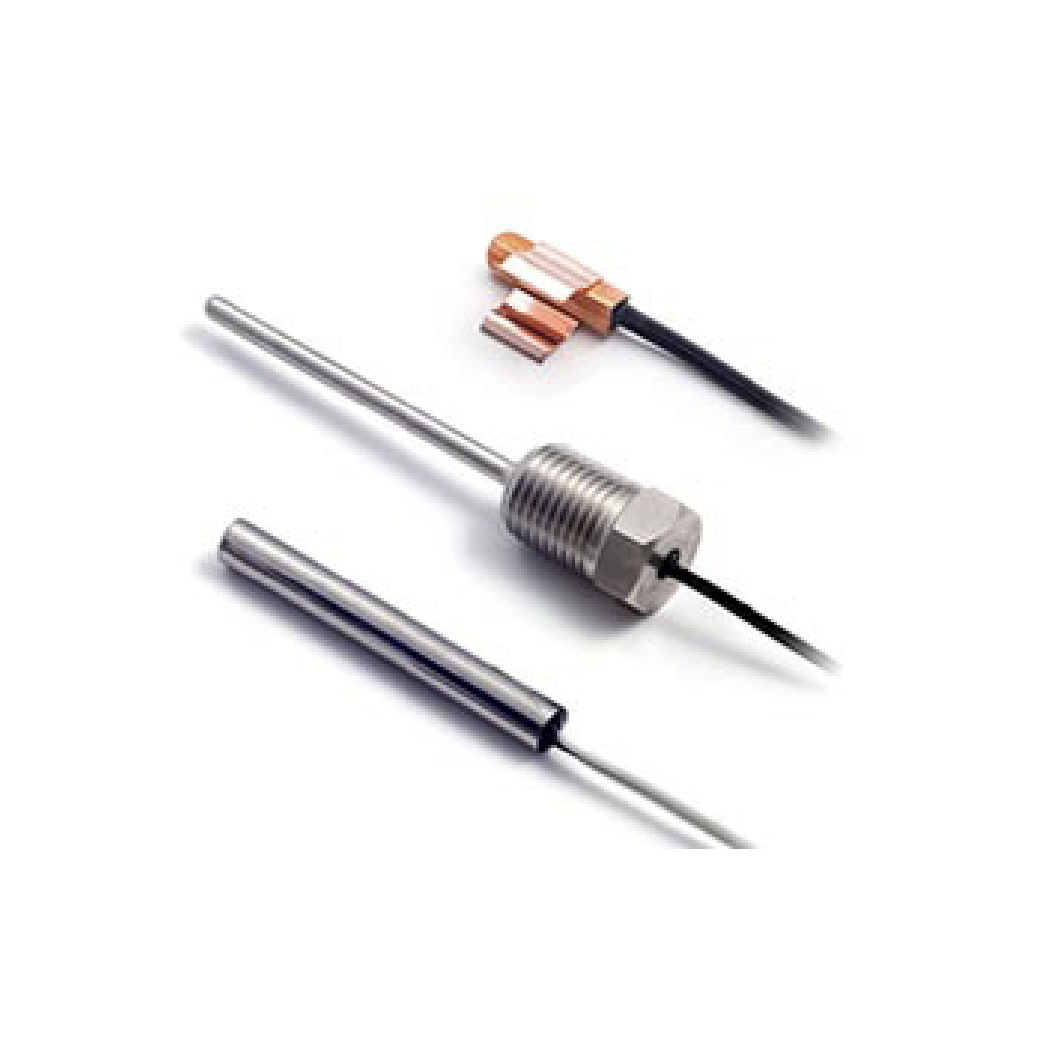

These sensors are often housed in flexible cables or semi-rigid probes and come in different lengths to match the size and layout of the space being measured.

How Averaging Sensors Differ from Standard Probes

Standard probes read temperature at a single point. That works well in controlled environments, but in large areas with varying thermal conditions a single point sensor may provide inaccurate data.

Averaging sensors collect input from multiple points along their length and combine it into one output. This gives a more accurate indication of the systems overall thermal status.

They’re usually longer and more flexible, suited for ducts or extended surfaces. Standard probes are usually rigid and made for fixed point temperature measurements.

How Averaging Sensors Work

Averaging sensors operate using a set of thermistors placed at intervals along a flexible or rigid averaging assembly. Each sensing point detects its local temperature, but the sensor doesn’t report these individually. Instead, it blends the input into one resistance value that reflects an average temperature of the overall area being sensed.

This design helps stabilize the temperature signal in areas where readings can fluctuate from point to point. Instead of overreacting to thermal spikes near a vent or draft, the system receives a more consistent signal tied to the full space being measured.

Most averaging sensors use a parallel circuit to keep the output predictable and compatible with standard controllers. This approach supports smoother control responses and avoids overcorrection based on isolated temperature swings.

Applications of Thermistor Averaging Sensors

These sensors are used in systems that require temperature input from more than one location. Common examples include HVAC ductwork, large enclosures, and any equipment with uneven thermal conditions.

HVAC and Building Automation

In HVAC systems, temperature readings can be skewed by vents, air movement, or heat from nearby equipment. This can cause uneven zone control or unnecessary cycling.

Thermistor averaging sensors reduce that risk by collecting input from multiple points along the duct. The output gives a balanced reading that helps maintain steady performance across the system.

In building automation, this leads to more accurate feedback and less need for manual correction.

Medical Equipment and Lab Environments

In lab settings and medical devices, even small temperature changes can affect performance. Equipment like incubators, refrigeration units, and climate-controlled storage often requires a uniform environment across shelves, chambers, or enclosures.

Thermistor averaging sensors help maintain that consistency by monitoring multiple points inside the controlled space. Instead of reacting to a warm or cool spot, the system adjusts based on a more complete view of overall internal conditions.

Industrial and Process Control Systems

Large equipment and enclosures often develop uneven temperature zones during operation. Heat from motors, drives, or power supplies can cause local hot spots that don’t represent overall conditions.

Averaging sensors give a more balanced view of temperature across these areas. This helps maintain safe operating ranges, improves control accuracy, and reduces the risk of overcorrecting based on a single reading.

They’re also used in temperature-sensitive production processes, where tight control is needed to maintain quality.

Advantages of Using Averaging Sensors

These sensors offer practical benefits across a range of systems. They help improve data quality, reduce system noise caused by fluctuating readings, and contribute to more stable operation over time.

Improved Temperature Accuracy Over Larger Areas

Temperature can vary across ducts, panels, or enclosures. A single sensor might catch a draft or hotspot, while missing the overall pattern.

Averaging sensors reduces that risk by gathering data from multiple points and smoothing out localized shifts. This helps maintain steady control and avoids unnecessary system reactions based on outliers.

Enhanced Reliability in Variable Environments

Systems exposed to shifting airflow, equipment heat, or irregular loads often see quick changes in temperature. These fluctuations can cause inconsistent readings and unnecessary adjustments.

Averaging sensors help reduce that issue. Multiple sensing points spread across the space produce a steadier signal that reflects general conditions rather than isolated spikes.

Versatility in Sensor Placement and Installation

Averaging sensors offer flexible mounting options for a wide range of system layouts. They’re available in different lengths and formats to fit tight spaces, follow long duct runs, or cover extended surfaces.

This makes them a practical choice for engineers and system designers working around size constraints or uneven heat distribution.

Why Choose EI Sensor for Your Temperature Sensing Needs

EI Sensor manufactures high-quality thermistor averaging sensors for HVAC, medical, industrial, and other demanding applications. Our sensors are built for accuracy, long-term reliability, and compatibility with real-world system requirements.

We work directly with OEMs and engineers to develop both standard and custom sensing solutions. Our focus is on delivering components that meet application-specific needs without overcomplicating the process.

Email sales@ei-sensor.com to start a conversation about your temperature sensing project or request design support.